Interactive teaching module for vehicle control systems

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

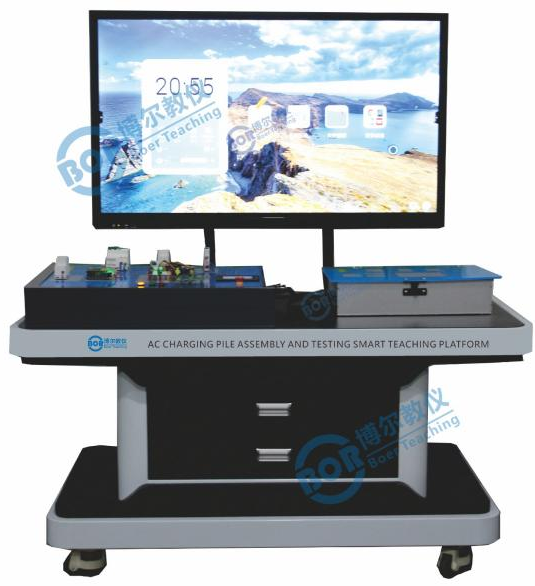

Product Overview:

The New Energy Vehicle Electronic Control System Training Platform uses a DC brushless drive motor, motor controller, energy system (power battery system), operating parameter monitoring system, and operation control system to simulate the regenerative braking energy recovery of electric vehicles. Through demonstrations of the AC motor control system's operation, it tests students' comprehension and hands-on skills, allows them to view circuit diagrams, analyze the relationships between components, and understand the working state of the DC motor control system.

Features:

1. The main components are horizontally mounted on the training platform, with four self-locking casters at the bottom for flexible movement and fixation. 1. The rational design and layout allow students to easily disassemble and intuitively understand the system's internal structure. Furthermore, the training platform is equipped with safety protection devices designed by our company, effectively protecting students during disassembly, assembly, and learning.

2. The carefully designed software system of this experimental platform features a beautiful and smooth interface, user-friendly interaction, and convenient student operation. Innovative touch interaction brings more learning enjoyment to students.

3. The training platform is based on a wireless network. While students are learning on the platform, teachers can inject various faults into the platform using the accompanying tablet, effectively evaluating students or providing instruction.

4. The 55-inch intelligent display system displays detailed circuit schematics, including all electrical parameters and component interface pin definitions, as well as complete circuit diagrams. The circuit diagram has test points, allowing students to use our company's virtual multimeter to measure and read data from each test point.

5. The training platform is equipped with numerous test ports, enabling real-time monitoring of information under various conditions using a multimeter and oscilloscope.

6. All core components use original vehicle parts, ensuring the training platform is identical to the real vehicle. The electrical connections of all components on the training platform are consistent with the real vehicle.

7. Supporting teaching materials are provided, including detailed platform description files, electrical parameters and pin definitions for all component interfaces, and complete circuit diagrams.

8. This training platform has a testing and fault simulation system, capable of testing and analyzing various fault phenomena and mechanisms of permanent magnet synchronous motors, facilitating students' mastery of fault detection.

Technical Specifications:

Car Dimensions: 4865 × 1832 × 1469 mm(Length × Width × Height)

Beat Dimensions: 1500 × 1000 × 1700 mm (Length × Width × Height)

Power Supply: Original vehicle device

Operating Temperature: -40℃ ~ +50℃