Loader Basic Electrical Training Platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

Product Introduction:

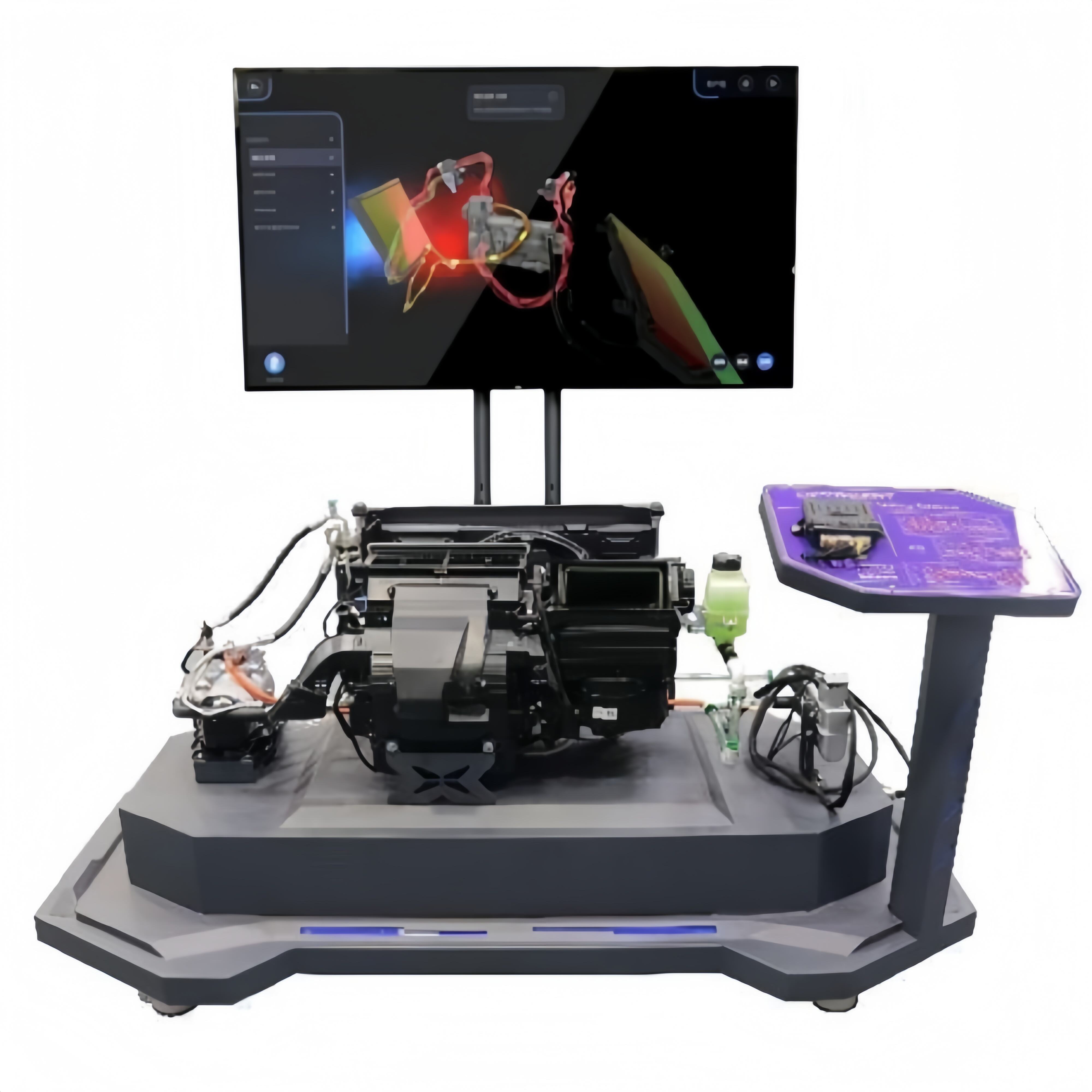

This equipment uses the original electrical control system of a loader as its base, fully demonstrating the composition and operation of the entire loader's electrical control system.

Features:

1. A fully functional loader's electrical system, showcasing the composition of the instrument system, lighting system, wiper system, starting system, and charging system.

2. Operation of various electrical switches and buttons realistically demonstrates the operation of the loader's instrument system, lighting system, wiper system, starting system, and charging system.

3. Each electrical component on the training platform panel has a connector. Referring to the accompanying circuit diagram or maintenance manual, connecting to the intermediate wiring harness helps train students to read diagrams and connect terminals.

4. The training platform panel is equipped with testing terminals, allowing direct testing of the electrical signals of each component in the loader's electrical system, such as voltage, current, and frequency.

5. The training platform's base frame is constructed of welded steel with a powder-coated finish. It features self-locking casters, ensuring flexible movement, safety, reliability, and durability.

Technical Specifications:

External Power Supply: AC 220V

Operating Voltage: 24V

Operating Ambient Temperature: -40℃~+50℃

Dimensions: 1700×1100×800mm

Basic Configuration:

1. Loader Electrical Circuit Board (can be configured according to user requirements): 1 piece

2. Battery: 1 unit

3. Radio: 1 unit

4. Horn: 2 units

5. Ignition Switch: 1 unit

6. Combination Lights: 1 set

7. Instrument Panel: 1 set

8. Cigarette Lighter: 1 unit

9. Indicator Light Switch: 1 unit

10. Emergency Brake Switch: 1 unit

11. Fault Setting Controller: 1 unit

12. Intelligent Fault Setting and Assessment System: 1 set

Practical Training Projects:

1. Understanding Basic Electrical Components of a Loader

2. Demonstration, Teaching, and Experiment of the Operation of Basic Electrical Components of a Loader

3. Sensor Signal Detection and Simulation Experiments

4. Fault Setting Drills, Troubleshooting, Assessment, and Experiments

5. Functions and Applications of Loader Instruments

6. Standard Values for Testing Various Electrical Components of a Loader

7. Testing and Repair Teaching in Vocational School Electrical Courses, etc.