Pure Electric Vehicle Drive System Training Platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

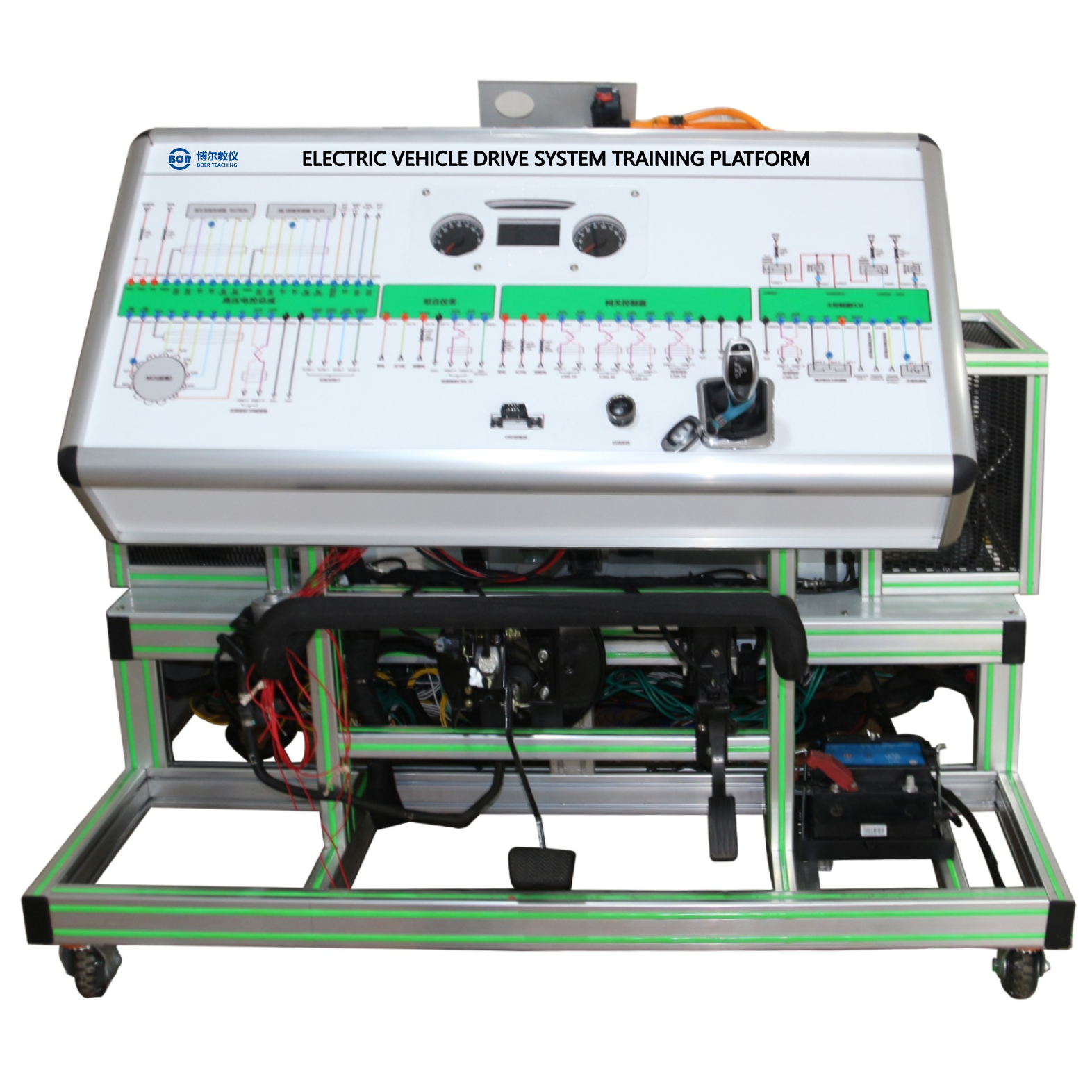

Product Overview:

This training platform is based on real electric vehicle components and demonstrates the working principles and processes of electric vehicle drive systems. For safety reasons, a low-voltage system, safe for human use, simulates the operation of a high-voltage system.

Main Components: 72V 50Ah lithium iron phosphate battery pack, lithium battery management system module, AC stepper motor, 5KW motor controller, instrument cluster, DC-DC power converter, 7-inch information display, gear shift switch, on-board charger, charging gun, high-voltage box, rear reduction axle, ignition switch, low-voltage battery, relays, charging plug, maintenance switch, mobile chassis, etc.

Features:

1. A realistic and operational electric vehicle powertrain system, fully demonstrating the overall operation of the electric vehicle powertrain system.

2. Demonstrates all components and structures of the electric vehicle drive system.

3. Demonstrates the operating status of core components such as the power battery pack, battery management system, and high-voltage system, simulating high-voltage system operation through a human-safe 72V low-voltage system.

4. Equipped with a touchscreen display: battery information such as charging/discharging current, voltage, temperature, and SOC.

5. The training platform panel is equipped with a motor voltage tester and a motor current tester, which can display the parameter changes of the motor in real time.

6. The training platform panel is equipped with test terminals, allowing direct testing of the electrical signals of the motor controller and battery controller pins, such as resistance, voltage, current, and waveform signals. This meets students' needs for circuit testing and performance debugging, and enables real-time fault setting and troubleshooting training.

7. A multi-functional fault simulation diagnostic box is included, using fault troubleshooting as the course introduction. During task implementation, it enhances students' comprehensive professional skills in fault diagnosis and troubleshooting, emphasizing the ability to execute logical diagnostics and independently plan and complete tasks.

8. Fault setting uses "short-circuit plugs" to connect the main controller and actuator or sensor wiring harnesses respectively. Disconnecting the plugs sets the fault. Alternatively, voltage, resistance, and grounding methods can be used to simulate complex fault phenomena such as sensor or actuator damage, poor contact, and short circuits.

9. The experimental platform has a horizontal tabletop with a width of at least 30cm, facilitating the placement of testing instruments and learning resources.

Technical Specifications:

Dimensions: 1500×1500×1000mm (Length × Width × Height)

Operating Power Supply: 220VAC/ 50Hz

Operating Temperature: -40℃ ~+50℃