Automotive Electronic Ignition and Fuel Injection Training Platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

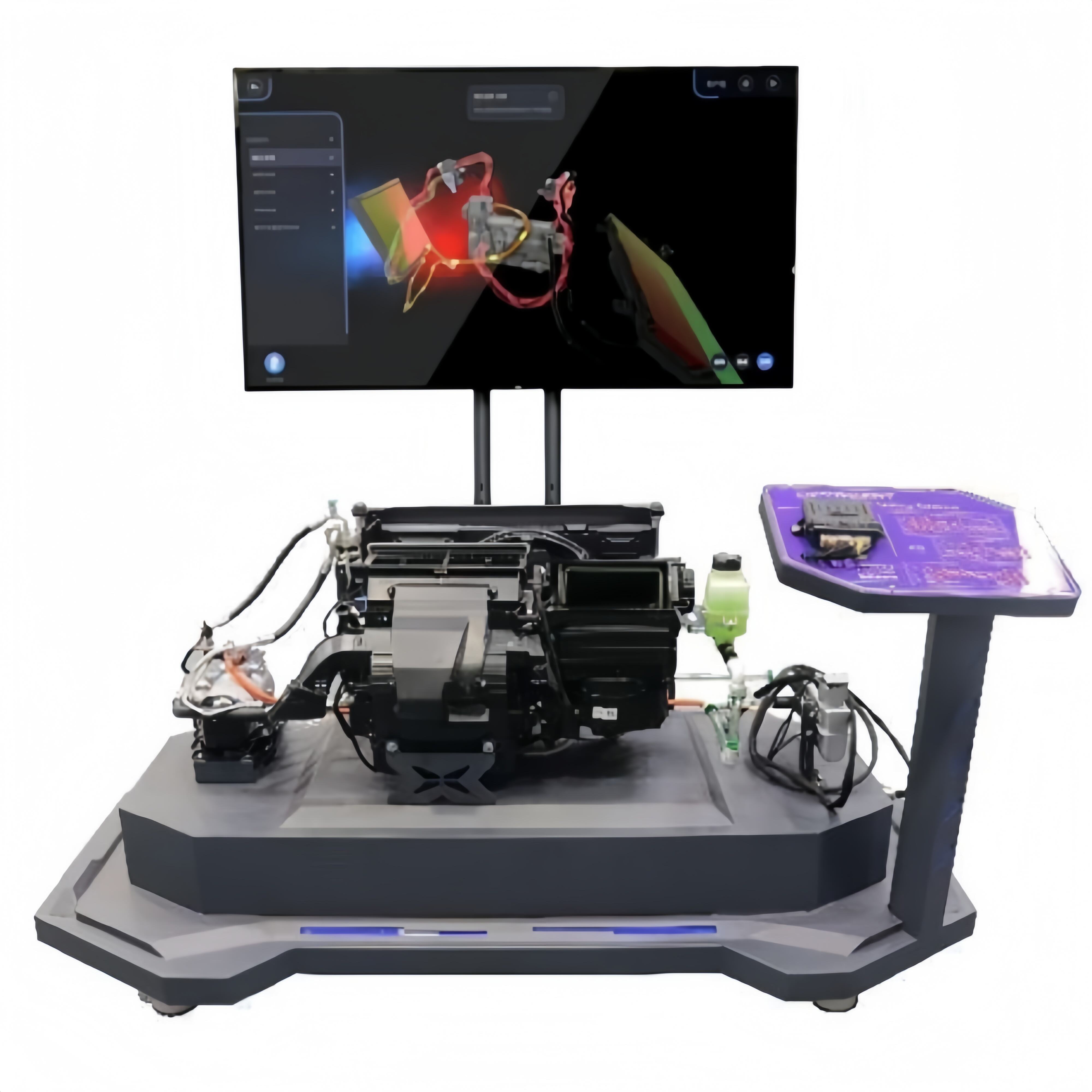

Product Overview:

Engine Ignition and Injection System Demonstration Boards are typically based on materials from real engine electronic control systems, such as those found in Volkswagen Passat models. By simulating engine operation, they demonstrate the working process of the engine electronic control system (ignition and injection), allowing trainees to intuitively understand the system's operating principles and practical operation.

The Engine Ignition and Injection System Demonstration Board uses real components of the engine ignition and injection system, fully demonstrating its composition and working process. It is suitable for schools' teaching needs in the theory and practical training of engine ignition and injection systems.

Features:

1. Realistic and Operable: The demonstration board incorporates a real engine ignition and injection system, simulating the actual engine operation process, including ignition and fuel injection.

2. Teaching Panel: The demonstration board features a complete schematic diagram of the electronic control system and includes testing terminals, allowing for the detection of various signal parameters from sensors and actuators, such as voltage, resistance, and frequency, using instruments.

3. Demonstration Function: By operating switches and buttons, the operation of the engine's electronic control system (ignition and fuel injection) can be realistically demonstrated, including the adjustment of parameters such as ignition timing and fuel injection quantity.

4. Fault Diagnosis: Some teaching boards are also equipped with a fault simulation system, which can simulate common faults in actual operating conditions to help trainees learn fault diagnosis methods and troubleshooting techniques.

5. Safety Protection: Teaching boards typically have safety protection functions, such as short-circuit protection and overload protection, to ensure safety during use.

Product Components:

1. Mobile Stand:

Equipped with an integrated circuit sensor fault setter, external 220V AC lighting power supply, converting high-power AC power to regulated 12V DC, etc.

Dimensions: 1300mm*650mm*1750mm (L*W*H)

Operating Power Supply: 12V DC

Operating Temperature: -40℃ ~ +50℃

2. Teaching Panel:

Ignition switch, OBD-II diagnostic connector (data communication interface), engine control unit (ECU), speed sensor, throttle position sensor, coolant temperature sensor, oxygen sensor, knock sensor, fuel injectors, fuel injection rails and gauge cups, relays, etc.

Ignition system (ignition wires, high-voltage ignition coil, spark plugs)

Sensor and actuator indicator lights

Colored diagram of the engine control system structure and circuit working principle, external test terminals.

Training Projects:

Complete Training on the Composition and Structure of Sensors and Actuators in Automotive Electronic Control Systems

Detection of Sensor Signal Parameters in Automotive Electronic Control Systems

Detection of Operating Voltage of Actuators in Automotive Electronic Control Systems

Circuit Analysis and Testing of Automotive Electronic Control Systems

Practical Demonstration of Ignition/Fuel Injection in Automotive Electronic Control Systems

Fault Diagnosis of Automotive Electronic Control Systems