High-voltage connector insertion and removal training platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

Product Overview:

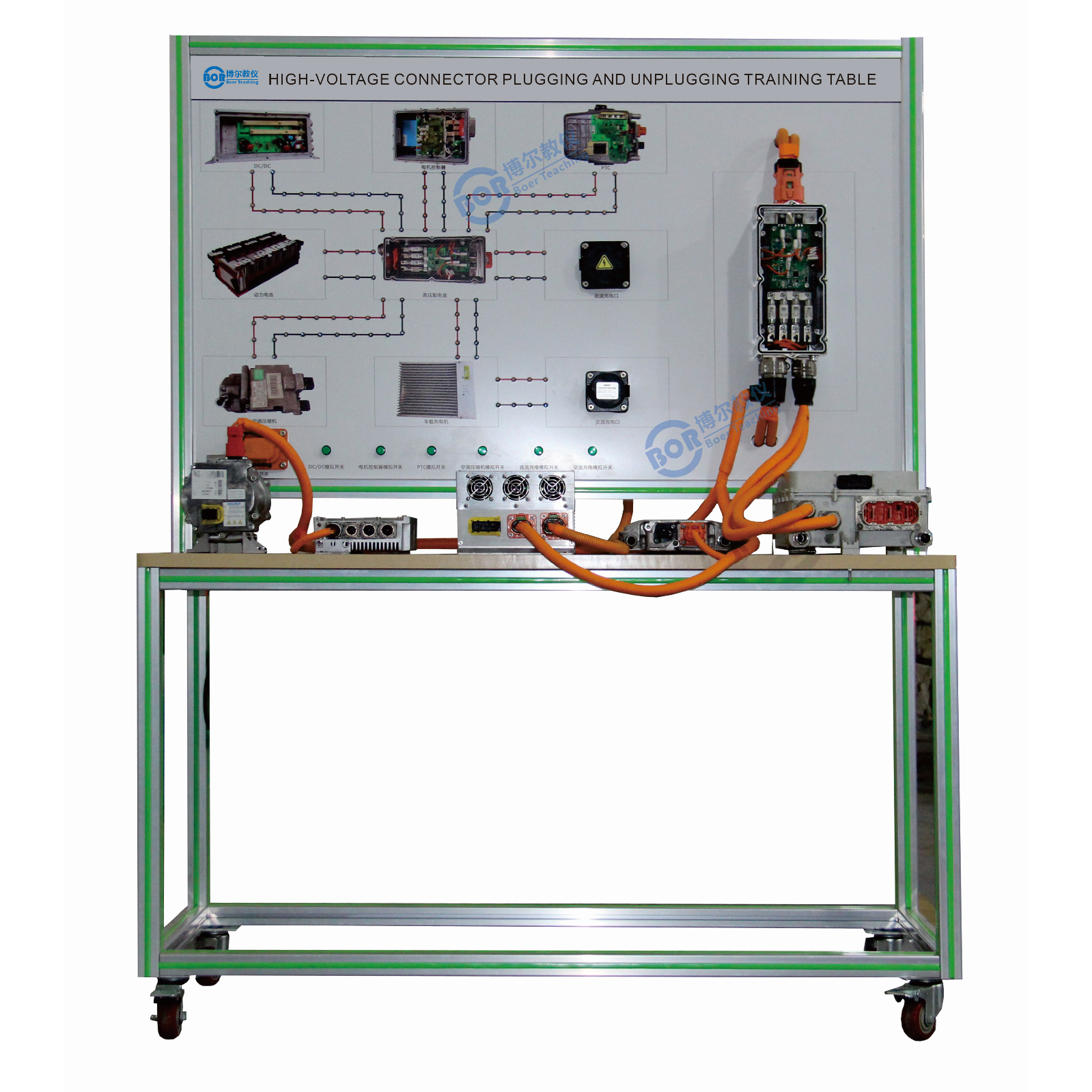

This product uses high-voltage connectors for electric vehicles, supplied to companies like Geely, BAIC New Energy, and Yutong Bus. Installed on a dedicated power battery pack enclosure, it allows trainees to practice plugging and unplugging the connectors, learning the consequences of improper operation. This provides essential basic knowledge for the safe operation of new energy electric vehicles.

Features:

Utilizes high-voltage connectors from new energy vehicles, installed on a dedicated power battery pack enclosure. Trainees repeatedly plug and unplug the connectors even without power.

The high-voltage connector plugs and sockets use the same cables as the power battery pack, with electrical connections identical to those in the actual vehicle, and are clearly labeled.

The panel illustrates the plugging and unplugging methods and precautions for each high-voltage connector.

Supply includes auxiliary resources such as instructions for plugging and unplugging maintenance switches, discharge positive and negative connectors, and charging positive and negative connectors.

Four self-locking swivel casters are installed at the bottom.

The selected mainstream pure electric permanent magnet synchronous motor and controller are connected via a high-voltage cable divided into two sections. One end is fixedly connected to the U/V/W high-voltage interface of the permanent magnet synchronous motor, using the same plug as the original vehicle. The other end connects to the motor controller, with an additional high-voltage quick-connect plug in the middle. This plug features a high-voltage interlock; disconnecting the high-voltage interlock circuit de-energizes the entire system, facilitating teaching high-voltage interlock circuit control.

The testing panel is made of acrylic material with a special primer coating. It is equipped with protective testing terminals, whose names are silkscreened in white lettering.

The accompanying New Energy Vehicle Drive System Teaching Resource Package Software V1.0 uses 3D animation to explain the structure and control principles of mainstream new energy vehicle drive motor assemblies.

Technical Specifications:

Dimensions: 1400x700x1450mm (Length*Width*Height)

Operating Temperature: -20°C~+40°C