Electric drive assembly, adjustment and maintenance work platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

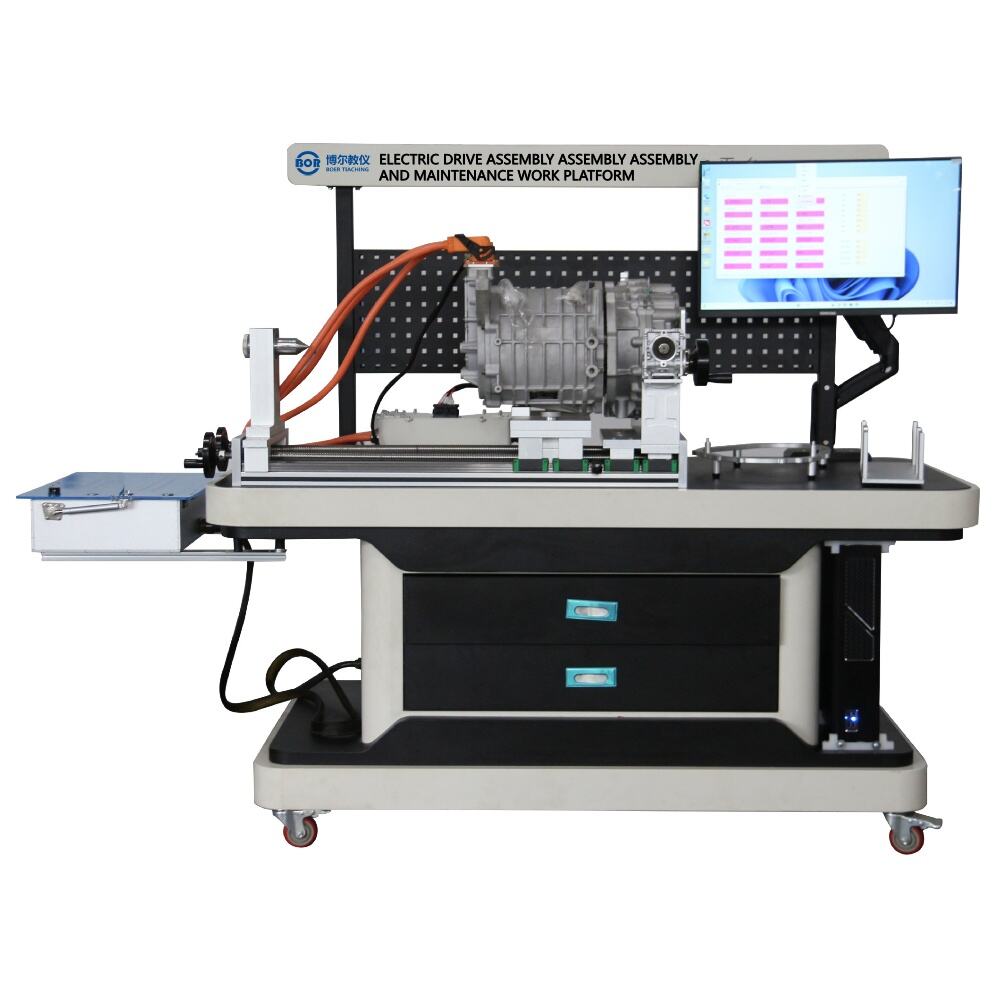

Product Overview:

The electric drive assembly, adjustment, and maintenance work platform can meet the needs of disassembling and assembling reducer assemblies, drive motor stator and rotor disassembly and assembly, drive motor dynamic testing, and drive motor static testing, thereby cultivating students' abilities in understanding the structure of electric drive systems, component inspection, and component assembly and adjustment.

This product meets the functional requirements of vocational schools for the assembly and testing of electric drive systems and is suitable for theoretical teaching of new energy vehicle drive systems in various schools.

It is suitable for teaching needs such as drive system disassembly and maintenance training, drive system structure and principle understanding, and high-voltage system safety operation.

Features:

1. The motor assembly and adjustment area consists of a motor assembly machine, drive motor, motor controller, reducer, reducer tilting mechanism, hand crank, etc., and can be used for drive motor assembly disassembly, repair, and adjustment, as well as reducer assembly, adjustment, repair, and measurement operations.

2. The drive motor is selected from the original drive motor of the new energy vehicle, mainly including the rotor assembly, stator assembly, three-phase adapter board, three-phase terminals, rear end cover, temperature sensor, resolver sensor, etc., and is equipped with an assembly machine to meet the user's needs for disassembling, assembling, and debugging the drive motor.

3. The drive motor assembly machine should include components such as long ejector pins, short ejector pins, stator fixing plate, lead screw and nut mechanism, locking slider, and hand-cranked assembly machine base. The assembly machine should be manually controlled, using a hand-cranked wheel to control the movement of components during the motor disassembly and assembly process, to achieve the purpose of properly assembling and separating the motor stator assembly and rotor assembly. Simultaneously, during the disassembly and assembly process, it should be able to measure data such as rotor magnetic induction intensity, three-phase winding cold DC resistance, and insulation resistance of the three-phase windings to the temperature sensor.

4. The main structure of the assembly machine is made of aluminum profile cutting and machining. The lead screw module is manufactured strictly according to lead screw machining technology, through a series of processing steps including cold drawing, knurling, threading, straightening, cutting, and chamfering. Electroplating surface treatment provides rust and corrosion resistance.

5. The fault detection box should consist of machined aluminum components, support rods, magnetic closure, mechanical lock, rubber feet, hinges, W-transfer aluminum measuring panel, measuring circuit board, measuring circuit board protective plate, fault setting panel, fault setting board liner, fault setting circuit board, fault setting circuit board pad, ignition switch, gear switch, brake switch, accelerator switch, etc.

6. The measuring panel should use printed aluminum anodizing with an outer insulating film treatment to protect the printed circuit diagram from scratches and abrasions while ensuring insulation. Fault diagnosis and data measurement can also be performed through the circuit diagram on the measuring panel. The measuring circuit board should have 2mm measuring terminals (with insulating sleeves) soldered on for use with multimeter probes.

Technical Specifications:

Dimensions: 1650×820×1600mm (L×W×H)

Power Supply: 12V DC

Operating Temperature: -10℃~+40℃