New Energy Vehicle Electric Steering Power Assist EPS Linkage Training Platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

Product Overview:

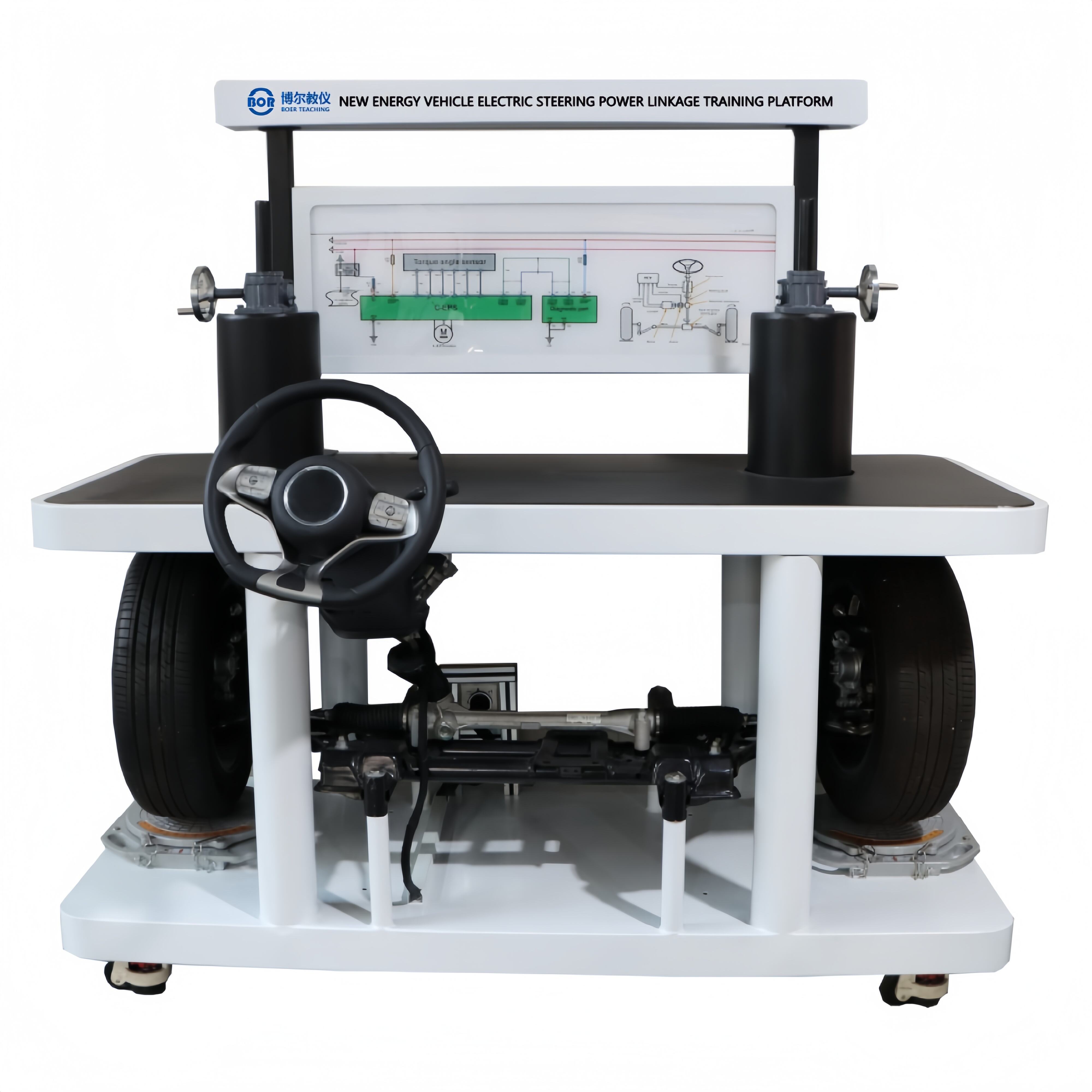

Based on a BYD pure electric vehicle's power steering system, this product includes the steering gear, servo motor, steering column, steering wheel, steering front axle, and tires. It is suitable for vocational schools and training institutions for learning about power steering systems in pure electric vehicles.

Features:

1. This course provides practical training in understanding the BYD pure electric vehicle's EPS (Electric Power Steering) system, its structure, and operation. The following knowledge points will be demonstrated, learned, and practiced: the functions and characteristics of electric power steering, the working principle of EPS, common power steering malfunctions, and diagnostic methods.

2. Intelligent fault assessment function: This system consists of two independent systems: a teacher fault setting terminal and a student answering terminal. The system is installed on a mobile terminal. Teachers can connect to the fault setting module using their mobile teaching terminal to set faults. After setting the faults, students can take the assessment using their mobile learning terminal. The assessment results are automatically stored in the device execution module, allowing teachers to easily check each student's scores. 3. To facilitate sensor and actuator identification and measurement, and to replicate the real-vehicle testing scenario while minimizing connector damage from plug insertion and removal, a ≥5cm testing terminal must be connected in parallel next to the original vehicle wiring harness connector. This testing terminal is made of transparent acrylic material, laser-engraved and flatbed-painted, and its shape must match the original vehicle connector's planar shape. Dedicated testing terminals are used, labeled with the measurement angle number and the sensor/actuator name. Electrical signals such as resistance, voltage, current, and frequency signals can be directly measured at the testing terminals of each sensor, actuator, and engine control unit pin.

4. Parameter changes under various conditions can be monitored in real-time using a multimeter and oscilloscope. The training platform is assembled from an aluminum profile frame and has four casters at the bottom for flexible movement. The casters also have self-locking devices for positional fixation.

5. The training platform panel features a circuit diagram and testing ports. Parameter changes under various conditions can be monitored in real-time using a multimeter and oscilloscope. A training manual is included with the training platform.

Technical Specifications:

Dimensions: 1300 × 820 × 1600mm (L × W × H)

Power Supply: DC 12V

Operating Temperature: -20℃ ~ +60℃