Plug-in Hybrid Drive System Testing and Training Platform

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

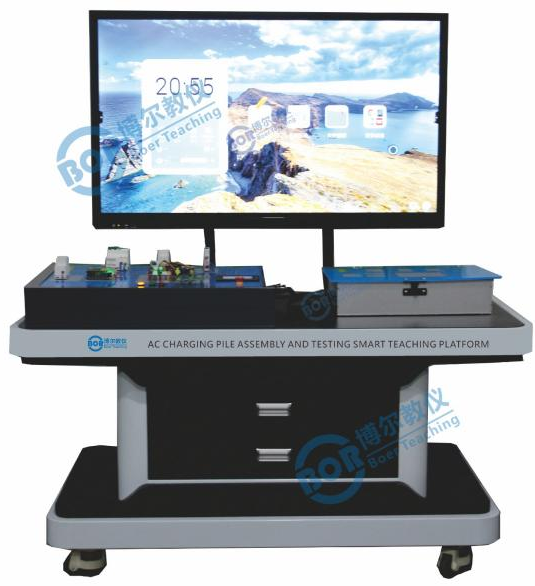

Product Overview:

The training platform mainly consists of a BYD new energy hybrid engine, transmission, M1 motor, M2 motor, frequency converter, HV battery, instrument panel, energy distribution display, gear shift lever, and a movable platform with locking casters.

Features:

1. The training platform can showcase innovative teaching designs. The base is made of high-strength aluminum profile, and the central column panel frame uses an integrated ABS molded cover.

2. The training platform can operate normally under various working conditions (including: idling, acceleration, deceleration, downhill, uphill, braking, loaded conditions, automatic/manual switching between hybrid and manual modes, etc.).

3. Common hybrid power system faults can be set. Through fault display, students can conduct fault analysis, detection, and diagnosis training, cultivating their fault analysis, detection, and diagnostic thinking abilities. No engine operation is required for starting; the electric motor can be used directly for starting, achieving a zero-displacement effect. During braking, residual energy can be used to charge the HV battery.

4. Equipped with a computer data detection port, it can connect to a dedicated or universal decoder to perform signal detection and analysis of various sensors, actuators, and electronic control units; perform ECU code lookup, fault code reading, fault code clearing, dynamic data stream reading, waveform analysis, waveform display, and actuator component test system login for the engine electronic control system.

5. The original instrument cluster can display engine speed and the operating status of other indicator lights. Fault indicators can display faults, and digital and analog meters provide a clear view of various sensors. It displays real-time dynamic and static signal parameters of the engine, showing voltage changes with different loads. An LED voltmeter displays real-time sensor changes, and injector pulse LEDs indicate the pulse width. An injection pulse width meter (real-time signal) is also included.

Technical Specifications:

Power Supply: DC12V

Operating Temperature: -40°C~50°C