Powertrain System - Hybrid Engine Management System Interaction Module

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

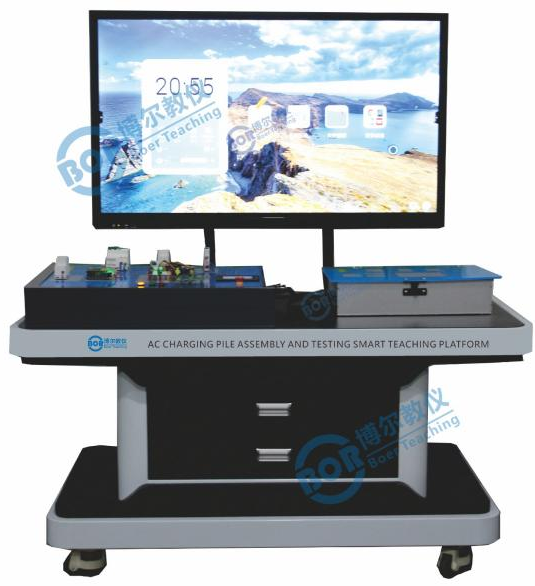

Product Overview:

This equipment, based on the Volkswagen Magotan hybrid system, is a new type of multi-functional hybrid power system testing and control device meticulously designed and developed to meet the current teaching needs of new energy vehicles. It focuses on seven major components: the engine system, transmission system, power battery, M1 motor, M2 motor, power management system, and power inverter.

The equipment boasts advanced technology, simple operation, and powerful functions, meeting the practical training needs of training institutions for extracting various data from new energy vehicle hybrid power systems, establishing and diagnosing various mechanical faults, and troubleshooting. Simultaneously, it provides comprehensive analysis, monitoring, and processing of various electronic control systems, realistically reproducing various faults encountered during actual operation of the hybrid power system. Accompanying targeted training materials effectively address teachers' technical shortcomings, significantly improving their teaching level.

During instruction, by changing the working state of each circuit, sensor, and actuator, students gain a comprehensive understanding of the fault phenomena of new energy hybrid power systems. This leads to familiarity with, mastery of, and independent control of new energy hybrid power systems, ultimately enabling students to independently operate the various state outputs of the new energy hybrid power system. The system involves five key learning processes: troubleshooting, restoring the normal operating trajectory of the new energy hybrid power system, and processing various output states.

Features:

1. Demonstration Function: All relevant systems are arranged logically, providing a clear visual representation of the structure and working principles of the hybrid power system control system and related accessories.

2. Operation Function: It can demonstrate the dynamic, static, and various operating conditions of the hybrid power system, meeting the needs for practical training and fault diagnosis of various operating conditions such as starting, idling acceleration, deceleration, and stopping.

3. Display Function: The instrument display unit shows various data of the hybrid power system, including coolant temperature, engine speed, engine oil pressure, and generator charging. A high-precision digital display shows the signal changes of each sensor in real time, allowing dynamic observation of the data changes. LED indicator lights show the working status of each actuator in real time.

4. Diagram Recognition Function: The testing panel displays high-definition circuit diagrams, component schematics, and structural diagrams of the hybrid power system and related systems. The lines are clear and the colors are varied. This course enables students to easily grasp the learning process from recognizing and understanding circuit diagrams to becoming proficient in reading and interpreting them, and ultimately being able to independently draw circuit diagrams. The electronic control unit (ECU) graphics are highlighted in color and labeled with plug information, part numbers, and codes. All component graphics are standardized and include internal structural schematics, making the learning intuitive, concise, and easy to understand.

5. Self-diagnostic function: Equipped with an external OBDⅡ diagnostic connector, it can connect to dedicated or universal decoders to query computer codes in the hybrid power system, read fault codes, clear fault codes, read dynamic data streams, analyze waveforms, test actuators, and log in to the system.

6. Testing function: The external wiring terminals on the testing console panel allow students to measure the values of each wire, each sensor, and the working status and changes of each actuator without disconnecting component plugs or damaging the original vehicle wiring harness. It also allows measurement of component voltage, resistance, current, waveforms, etc., through the terminals, providing real-time monitoring of the working status of each component.

7. Signal simulation function: The signal simulation system uses an adjustable signal simulation system, allowing for the arbitrary setting of any parameter of each major sensor, with stepless adjustment throughout the entire range.

8. Manual Fault Setting System: A standard fault setting system is installed in a concealed location on the test bench. This system simulates real-world faults, providing functions for understanding, judging, diagnosing, and troubleshooting.

9. Intelligent Fault Setting System: An optional intelligent assessment system is a computer-controlled teaching system that collects all fault data from all teaching equipment. It manages student information, automatically calculates scores, and allows assessment equipment to be assigned to each student. Student IDs are automatically transmitted, and students can be assessed in batches. It supports both single-machine and multi-machine assessment modes, allows for arbitrary combination or setting of equipment faults, and features a Chinese-language user interface. It allows for both online and offline assessments. Operation is simple and convenient for students and teachers.

10. Safety Protection Functions: A main power switch is installed between the battery and electrical equipment. When the test bench is not in use, the switch is turned off to protect the equipment and battery. High-speed and high-temperature components, such as the water tank and exhaust pipe, are protected with perforated panels. Safety nets and railings are used to enhance operational safety.

11. Mobile Teaching Function: The training platform is equipped with swivel casters with locking devices, ensuring convenient movement and reliable locking.

Technical Specifications:

Platform Dimensions: 900 × 600 × 1700mm (L × W × H)

Power Supply: 60AH battery/105AH

Operating Temperature: -40℃ ~ +50℃