- Overview

- Recommended Products

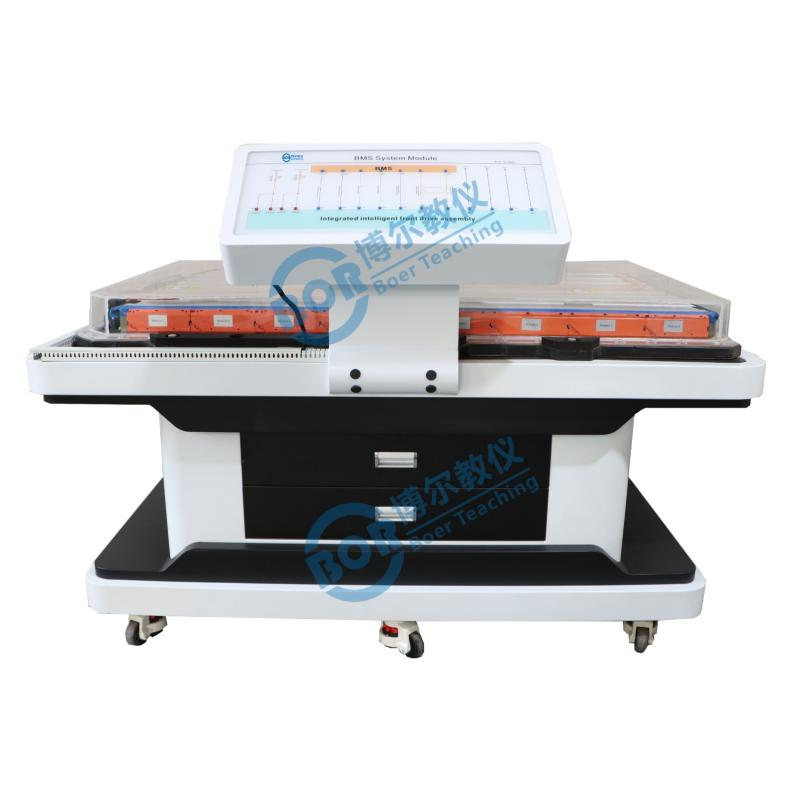

Product Overview:

Based on the real body of the pure electric vehicle power battery, including the power battery pack and the battery management unit, it fully demonstrates the internal structure, control principle and performance parameters of the power battery, which is suitable for the principle teaching needs of the pure electric vehicle power battery system in secondary and higher vocational colleges and training institutions.

Features:

The original BYD power battery pack (including BMS management system) is selected, and the power battery pack adopts a distributed battery management system, which is composed of a battery management controller (BMC), a battery information collector, and a battery sampling line. The main functions of the battery management controller include charge and discharge management, contactor control, power control, battery abnormal state alarm and protection, SOC/SOH calculation, self-test and communication functions. The main functions of the battery information collector include battery voltage sampling, temperature sampling, battery balancing, sampling line anomaly detection, etc.; The main function of the power battery sampling line is to connect the battery management controller and the battery information collector to realize the communication and information exchange between the two. The main components are installed on the platform, and the electrical connection method is the same as that of the actual vehicle, which can be easily disassembled after power failure, so that students can master the key points of disassembly and assembly of high-voltage system parts and safety protection in the process of disassembly and assembly; The upper cover of the power battery pack adopts an acrylic cover that is consistent with the appearance of the original car battery, which is more convenient for the observation of the internal structure of the battery. This training platform provides power source for the training stations such as "drive transmission system" and "air conditioning control system", and the connecting cable is matched by the original car, which is the same as the original car. The training bench is equipped with a 12V power grounding mechanical switch, which can disconnect the 12V grounding at any time and cut off the power supply of the whole system. Configure intelligent fault assessment function: It is mainly composed of two independent systems: the teacher's fault setting terminal and the student's answering terminal, which are installed on the mobile terminal. The mobile teaching terminal for teachers can be connected with the fault setting module of the integrated teaching aid for fault setting. After the fault setting is completed, the student answers the assessment through the student's mobile learning terminal, and the results after the assessment are automatically stored in the execution module of the device, which is convenient for the teacher to query the results of each student. In order to facilitate the identification and measurement of sensors and actuators, and to reduce the plug damage caused by sensor and actuator plug plugging and unplugging while restoring the real vehicle detection scene, it is required to connect the detection end of ≥5cm in parallel next to the original vehicle wiring harness plug, and the detection end is made of transparent acrylic material by laser engraving and flat plate spraying, and the shape is required to be the same as the plane shape of the original car plug, and the measuring end adopts a special detection terminal, and the number of the measurement angle position and the name of the sensor actuator are marked. The electrical signals of the pins of each sensor, actuator and engine control unit, such as resistance, voltage, current, frequency signal, etc., can be detected directly on the measuring terminal. With the help of multimeter and oscilloscopes, which is firm and reliable and will never change color, and 4 casters are installed at the bottom of the training platform, which can move flexibly, and the casters have a self-locking device to fix the position. The OBDII. interface fault code reading is carried out by using the real vehicle decoder to ensure the authenticity of the vehicle fault data and the authenticity of the operation to the greatest extent. The high-voltage components of the bench will be protected by high-transparency plexiglass, and the necessary mobile window can be opened for the plugging of high-voltage components, so as to ensure that the high-voltage components and cables in the equipment will not be damaged in the daily storage process, resulting in the hazard of deterioration of insulation performance. The training bench-top panels sprayed with circuit diagrams and equipped with detection ports, with the help of multimeter and oscilloscopes, real-time detection of parameter changes in various states. The training desk is equipped with a training instruction book.

Dimensions:

1300×820×1300 (L×W×H) Power supply: DC12V Operating temperature: -20°C~+60°C