Charging Management System Interaction Module

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

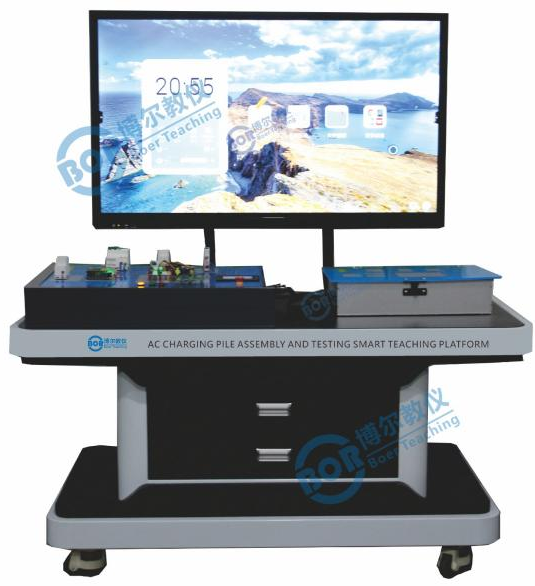

Product Overview:

This training system is based on a factory-installed hybrid vehicle powertrain. All systems of the hybrid vehicle are operational, allowing for real-world operation of starting, acceleration, deceleration, fault detection and diagnosis, fault simulation and troubleshooting, etc., realistically demonstrating the structure, principles, and working processes of each vehicle system. It is suitable for practical training needs in various types of colleges and training institutions for the theory and maintenance of hybrid vehicles.

The testing console can be removed, and the hybrid vehicle can still be driven normally. This training system features comprehensive training functions, convenient operation, safety, reliability, and an aesthetically pleasing design.

Features:

1. All systems of the hybrid vehicle operate normally, retaining the complete powertrain and control systems. The testing console connects to the vehicle via aviation plugs and connecting cables, maintaining all original vehicle functions. The testing console can be removed, and the vehicle can still be driven normally.

2. A movable testing workbench allows for hands-on training in testing various control systems: electronic engine and transmission control systems; ABS control system; air conditioning control system; lighting and body electrical control systems; and hybrid power control system.

3. The workbench panel is made of 4mm thick high-grade aluminum composite panel, which is corrosion-resistant, impact-resistant, stain-resistant, fire-resistant, and moisture-proof. The surface is treated with a special primer coating. The panel features a UV flatbed print of color circuit diagrams. Trainees can visually compare the circuit diagrams with the actual original vehicle's engine, transmission, ABS, air conditioning, lighting, and body electrical systems to understand and analyze the working principles of each control system.

4. The workbench panel is equipped with testing terminals, allowing direct testing and training of the original vehicle's engine, transmission, ABS, air conditioning, lighting, and body electrical control systems.

5. The workbench is equipped with a diagnostic connector. Hybrid vehicles and the workbench can be simultaneously connected to a dedicated or universal automotive decoder for self-diagnostic functions such as reading and clearing fault codes and reading data streams for the engine, automatic transmission, air conditioning system, and hybrid power control systems.

6. Hybrid vehicle maintenance and upkeep operations can be performed. The system enables disassembly, assembly, and operational condition demonstrations. The fault simulation system can simulate actual operating conditions and set various common system faults. The base of the testing platform is constructed with a welded steel structure, and the platform surface is finished with a baked enamel coating and features omnidirectional self-locking casters.

7. According to user requirements, the vehicle body sheet metal, interior trim, etc., can be cut apart, preserving the complete powertrain system, electrical and circuit control systems, and systems that allow the vehicle to operate independently. Depending on optional features, the vehicle can be longitudinally cut in half, including the left front and rear doors, engine hood, roof, and part of the floor. Sheet metal parts are smoothly cut and different structures are marked with different colors. Retained body panels, other interior trim, and paint are undamaged; cut areas are smooth and edged with adhesive strips to prevent scratches during training.

Technical Specifications:

Car Dimensions: 4865 × 1832 × 1469 (Length × Width × Height)

Bench Dimensions: 1740 × 600 × 1700 (Length × Width × Height)

Power Supply: Original vehicle assembly

Operating Temperature: -40℃ ~ +50℃