Interactive teaching module for high-voltage batteries and thermal management systems

Minimum Order : 1 Set

Warranty: 2 years

Delivery: EXW Guangzhou

Shipping Way: By Sea / Air / Express

Certification: ISO / GPSR / Copyrights / Patents...

OEM Service: Accept OEM Accept ODM

Customization: Logo / Size / Appearance / Material...

Technical Support: Software / Manual / Video / Technician

- Overview

- Recommended Products

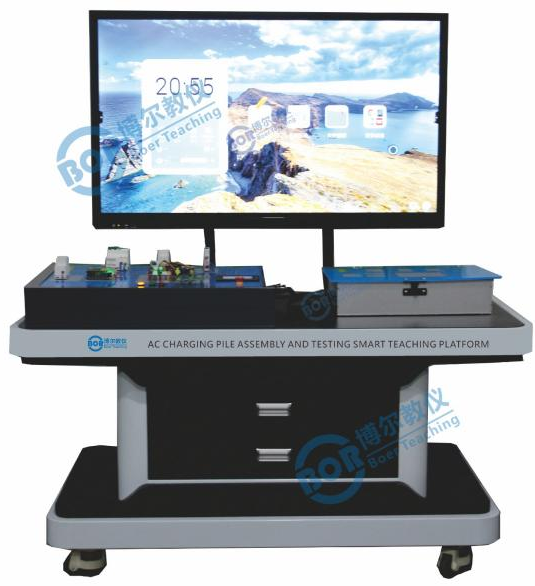

Product Overview:

New energy vehicles, as a crucial means of achieving the energy revolution, have seen electric vehicles become the most popular mode of transportation. The performance and stability of the high-voltage electrical components (battery pack and thermal management system), the core components of an electric vehicle, determine its overall quality.

Electric vehicles have now become a part of people's lives, and their safety performance must be guaranteed. Therefore, testing electric vehicle safety is particularly important. Electric vehicle safety mainly involves two aspects: the safety control strategies for the high-voltage electrical components and the high-voltage safety precautions and operating procedures during maintenance.

Features:

1. Demonstrates the physical components of an electric vehicle's high-voltage safety protection system, illustrating the electrical principles and power-on/off logic of the high-voltage system. It showcases the safety protection measures and testing of the high-voltage system. The power distribution system includes a main positive relay, a main negative relay, a pre-charge relay, and a pre-charge resistor, dynamically simulating the operating status and process of the entire vehicle's high-voltage safety system.

2. Includes an ignition switch, a real electric vehicle lithium battery pack and BMS system, an electric vehicle safety maintenance plug module, a high-voltage circuit simulation system, safety relay components, a leakage protection module, and simulated control switches.

3. Install a national standard charging port and charging gun for electric vehicles to realistically simulate electric vehicle charging operations. After the national standard charging gun is inserted into the charging port, the high-voltage safety system controls the safety relays via CAN-BUS communication, and the charging status is simultaneously displayed on a 7-inch color screen display via CAN-BUS communication, with no high-voltage output.

4. The electric vehicle high-voltage safety protection system components, including safety relays (main positive relay, main negative relay, and pre-charge relay), can be normally controlled and operated through the electric vehicle's high-voltage safety system control unit; the high-voltage safety system control unit uses CAN-BUS communication for control.

5. The high-voltage safety system control unit uses CAN-BUS communication to display safety alarm and other signal information. After the high-voltage safety system alarms, it controls the safety relays to operate via CAN-BUS communication, with no high-voltage output. This enables practical training on high-voltage safety interlocking, self-locking, leakage protection, and high-voltage system shutdown.

6. The BMS control unit's 7-inch color screen display shows real-time signals such as battery voltage, current, temperature, and high-voltage leakage status.

7. Lithium Battery and Safety Management System: This system performs real-time monitoring of power battery parameters, fault diagnosis, SOC estimation, short-circuit protection, insulation detection, charge/discharge control, and equalization. It interacts with the on-board charger (with CAN communication) via a CAN bus.

8. The panel is made of 4mm thick aluminum composite panel. The vertically mounted panel features a full-color standard system diagram printed on a UV flatbed printer. Trainees can visually compare the diagram with the actual system to understand and analyze its working principles. The panel is equipped with test terminals, allowing direct testing of electrical signals from system circuit components, such as resistance, voltage, current, and frequency. A fault simulation system is included, enabling the setting and troubleshooting of low-voltage circuit system faults. It allows for the setting and assessment of 12 common fault points.

9. The equipment frame is constructed using two types of integrated all-aluminum alloy profiles: 40mm×40mm and 40mm×80mm. It is oil-resistant, corrosion-resistant, and easy to clean. The tabletop is 40cm wide and covered with 32mm thick colored high-density composite board, ensuring durability and rust resistance. It comes with four self-locking casters for easy movement. Accompanying training (experiment) manuals and other teaching materials are provided, including explanations of working principles, training projects, fault settings, and analysis.

10. Safety protection devices are installed: emergency stop switch, mechanical main power switch, maintenance switch, protective covers for rotating parts, high-voltage safety protection devices, and warning signs.

Technical Specifications:

Car Dimensions: 4865 × 1832 × 1469 (Length × Width × Height)

Bench Dimensions: 1500 × 600 × 1700 (Length × Width × Height)

Power Supply: Original vehicle equipment

Operating Temperature: -40℃ ~ +50℃