- Overview

- Recommended Products

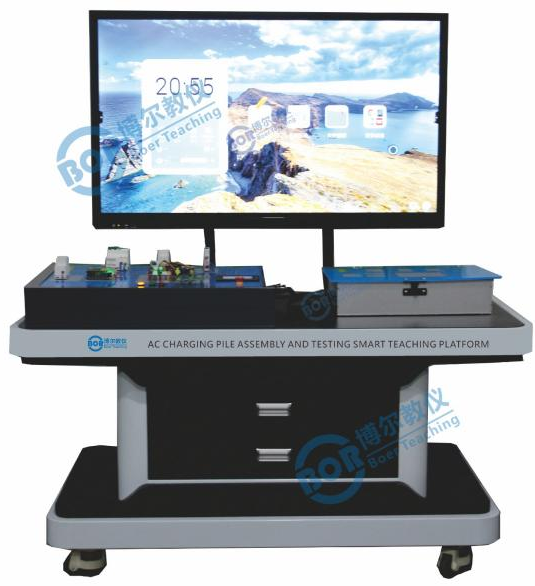

Product Overview:

As one of the important means to realize the energy revolution, new energy vehicles have become the most popular means of transportation, and the performance and stability of the high-voltage power part (battery pack and thermal management system) as the core components of electric vehicles determine the quality of an electric vehicle. At present, electric vehicles have entered people's lives, and their safety performance must be guaranteed. Therefore, the testing of electric vehicle safety is particularly important, and the safety of electric vehicles is mainly divided into two aspects. On the one hand, it is the safety control strategy of the high-voltage power part, and on the other hand, the high-voltage safety precautions and operating procedures during maintenance.

Features:

The physical components of the high-voltage safety protection system of electric vehicles are the basic components, which can reflect the electrical principle and power-up logic of the high-voltage system; The safety protection measures and safety detection of the high-voltage system, the installation of the total positive relay, the total negative relay, the pre-charge relay and the pre-charge resistance in the power distribution system can dynamically simulate the operation status and working process of the high-voltage safety system of the whole vehicle. Install ignition switches, real lithium battery packs and BMS systems for electric vehicles, plug modules for electric vehicle safety maintenance, high-voltage circuit simulation systems, safety relay components, leakage protection modules and analog manipulation switches. Install the national standard charging port and charging gun for electric vehicles to truly realize the charging operation of electric vehicles. After the national standard charging gun is inserted into the charging port of the equipment, the high-voltage safety system controls the safety relay to work through CAN-BUS communication, and the 7-inch color screen display through CAN-BUS communication synchronously displays the charging working conditions, and the high-voltage has no output. The high-voltage safety protection system device of electric vehicle, the safety relay (including the total positive relay, the total negative relay, and the pre-charged relay) can be controlled and worked normally through the high-voltage safety system control unit of the electric vehicle; The control unit of the high-voltage safety system is controlled by CAN-BUS communication. The control unit of the high-voltage safety system adopts CAN-BUS communication to display signal information such as safety alarms. After the high-voltage safety system alarms, the safety relay is controlled to work through CAN-BUS communication, and the high-voltage has no output. Realize high-voltage safety interlocking, self-locking, leakage protection, high-voltage system suspension and other practical training. The 7-inch color screen display of the BMS control unit displays the real signal of the battery voltage, current, temperature, high-voltage leakage and other statuses. Lithium battery and safety management system: real-time monitoring, fault diagnosis, SOC estimation, short-circuit protection, insulation detection, charge and discharge control, balancing and other functions of power battery parameters, and information interaction with on-board charger with CAN communication through CAN bus. The panel is made of 4mm thick aluminum-plastic panel, and the vertical mounting panel is printed with a complete standard system drawing board in color. Students can visually compare the drawing board with the actual object to understand and analyze the working principle of the system. The panel is equipped with a detection terminal, which can directly detect the electrical signals of the system circuit components, such as resistance, voltage, current, frequency signal, etc., on the panel. The installation of the fault simulation system can realize the fault setting and diagnosis and elimination of the low-voltage circuit system, and can set the setting of common faults and assess 12 fault points. The equipment frame is built with 40mm×40mm and 40mm×80mm two integrated all-aluminum alloy profiles, which are oil-resistant, corrosion-resistant and easy to clean, the table is 40CM wide, and the table top is paved with 32mm thick color high-density composite panels, which are durable and rusty, and have 4 universal casters with self-locking devices for easy movement. Supporting training (experiment) instruction and other teaching materials, including working principles, training items, fault settings and analysis and other key points. Install safety protection devices: emergency stop switches, mechanical power main switches, maintenance switches, protective covers for rotating parts, high-voltage safety guards and warning prompts.